What Is ETO Sterilization

- Home

- What Is ETO Sterilization

ETO Sterilization

Sterility forms the backbone of safe medical practice. Every syringe, catheter, surgical instrument, or implant must be free of harmful microorganisms before it touches a patient. Hospitals, pharmaceutical companies, and laboratories rely on different sterilization techniques to achieve this goal. Among them, ETO sterilization, also known as Ethylene Oxide sterilization or the gas sterilization method, remains one of the most effective solutions for sensitive medical devices.

Book Free Appointment

1L+

Happy Customers

25+

Qualified Doctors

50

Rooms

5000+

Successful Surgeries

Free

Consultation

24/7 Ambulance

Facility

Insurance

Claim Support

What Is ETO Sterilization?

ETO sterilization uses Ethylene Oxide gas to eliminate microorganisms from medical equipment. Unlike steam or heat-based methods, this technique operates at relatively low temperatures, making it ideal for items that cannot withstand heat or moisture.

The process works by disrupting the DNA and proteins of microorganisms, ensuring complete destruction of bacteria, viruses, fungi, and even resistant spores. Since many medical devices today are made of plastics, polymers, or electronics, the ETO process provides a reliable way to achieve sterility without causing damage.

Dr. Sasidhara Roa A

MBBS, MS

5000+ Successful Surgeries

11+ Years of experience

Dr. Sasidhara Rao A. is an experienced General and Laparoscopic Surgeon at Sree Sai Deepa Hospitals, Chandanagar, with over 11 years of expertise and 5000+ successful surgeries. He specializes in laparoscopic, laser, and microscopic surgeries, treating conditions like piles, fissures, varicose veins, and gallbladder issues.

Doctor’s Fellowships:

Fellowship - International Society of Coloproctology

Fellowship in Intimate Health

Fellowship in Diagnostic Endoscopy

How the Process Works

The Ethylene Oxide sterilization cycle typically involves four stages:

Preconditioning – The equipment is exposed to controlled humidity and temperature to prepare for sterilization. Moisture enhances the effectiveness of the gas.

Gas Exposure – The sterilization chamber is filled with ETO gas at specific concentrations. The gas penetrates packaging and device materials, destroying microorganisms in even the hardest-to-reach areas.

Aeration – After exposure, devices undergo aeration to remove residual gas. This step is vital since Ethylene Oxide can be harmful in high concentrations.

Validation – Biological and chemical indicators verify that sterilization has been successful.

Because of its ability to permeate packaging materials and complex device structures, ETO sterilization ensures even intricate or delicate medical instruments remain safe for patient use.

Applications in Healthcare

Ethylene Oxide sterilization is widely used across healthcare facilities and medical manufacturing. Some common applications include:

Single-use medical devices such as catheters, syringes, cannulas, and surgical implants.

Complex surgical tools like endoscopes and laparoscopic equipment that cannot tolerate heat.

Pharmaceutical products including sutures, dressings, and certain drug formulations.

Hospital supplies such as respiratory equipment, wound dressings, and dialysis components.

In fact, studies suggest that nearly half of all sterilized medical devices worldwide rely on the ETO process, highlighting its importance in global healthcare.

Get your surgery cost

Benefits of ETO Sterilization

The gas sterilization method offers several advantages over traditional techniques.

1. Compatibility with Sensitive Materials

Heat- and moisture-sensitive instruments, especially those made of plastics or electronics, remain intact when sterilized with Ethylene Oxide. This compatibility makes it invaluable for modern medical devices.

2. High Sterilization Efficacy

The ETO process destroys all microorganisms, including highly resistant bacterial spores. Its ability to reach hidden crevices and lumens ensures thorough disinfection.

3. Sterilization in Final Packaging

Medical products can be sterilized within their final sealed packaging. This means items remain sterile until use, minimizing contamination risks during handling.

4. Reduced Equipment Damage

Because it operates at low temperatures, the Ethylene Oxide method extends the lifespan of delicate instruments compared to high-heat sterilization.

5. International Acceptance

The process meets international standards such as ISO 11135, giving hospitals and manufacturers confidence in its reliability.

Accreditations

Saideepaneurocare Hospitals is NABH certified, a mark of excellence in patient safety and care. We follow stringent healthcare protocols and maintain world-class hygiene standards.

We are ISO 9001 certified, ensuring the highest standards in quality management and patient care. This certification reflects our commitment to efficient processes and continuous improvement in healthcare services.

Limitations and Challenges

Despite its many strengths, ETO sterilization faces some challenges.

Toxicity: Ethylene Oxide is a toxic and carcinogenic gas. Strict safety protocols, ventilation systems, and monitoring are essential to protect healthcare workers.

Time-Consuming: The entire cycle, including aeration, can take up to 24 hours, making it slower than other methods like hydrogen peroxide plasma sterilization.

Environmental Concerns: Because the gas is hazardous, emissions must be controlled. Hospitals and manufacturers use scrubbers and filters to minimize environmental impact.

Cost of Infrastructure: Setting up ETO facilities requires specialized chambers, aeration units, and monitoring devices, making it a costly investment.

Future of ETO Sterilization

The healthcare industry continues to improve the safety and efficiency of the gas sterilization method. Key advancements include:

Automated sterilization chambers with real-time monitoring to reduce errors and ensure precision.

Shortened aeration times through advanced aeration systems, helping speed up the sterilization cycle.

Safer gas blends that reduce toxicity while maintaining effectiveness.

Eco-friendly technologies to minimize environmental impact and meet global sustainability goals.

These innovations promise to make Ethylene Oxide sterilization safer, faster, and more sustainable without compromising reliability.

Why ETO Sterilization Matters for Patients

Patients rarely think about sterilization, yet their safety depends on it. Every time a surgeon inserts a catheter, performs laparoscopic surgery, or uses an implant, sterility ensures protection against infections. The ETO sterilization process silently safeguards patients by ensuring that medical devices are not only functional but also free from harmful microorganisms.

Hospitals that invest in this technology demonstrate their commitment to patient safety and international standards of care.

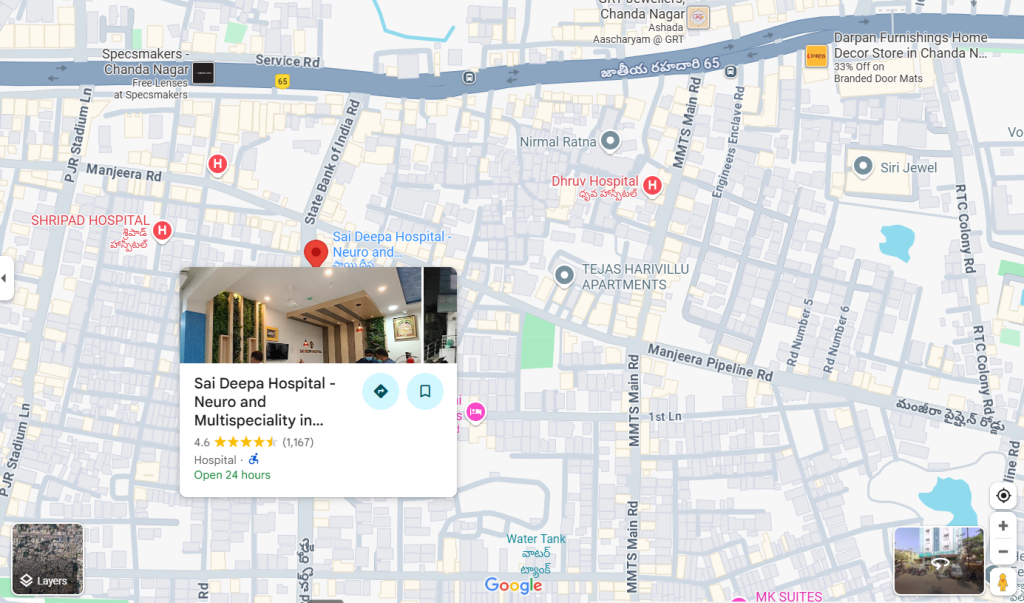

Sai Deepa Hospital - Neuro and Multispeciality

Plot no 387, Church road, Huda colony, Chanda Nagar, Hyderabad – 500050

Conclusion

ETO sterilization remains a cornerstone of modern healthcare. Its unmatched ability to sterilize heat-sensitive, complex, and packaged medical devices makes it irreplaceable in hospitals and manufacturing facilities. While concerns about toxicity, cost, and environmental impact exist, continuous innovation is addressing these challenges.

For patients, this means confidence that every medical device, from syringes to surgical implants, has undergone a thorough and proven sterilization process. For healthcare providers, it reinforces the commitment to safety, precision, and excellence in care.

As healthcare continues to evolve, Ethylene Oxide sterilization will remain a trusted guardian of sterility, ensuring safer treatments and better outcomes for millions worldwide.